As fundamental as Formula 1 testing

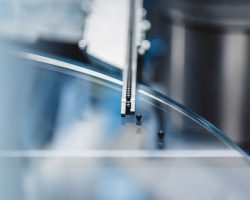

Optical sorting is a major part of the LAV.EL. Gomma production cycle, with sorters inspecting vast batches of O-rings and technical items extremely rapidly. Each of these modern machines is mounted with seven cameras that take a snapshot of each gasket from various angles and record any faults or irregularities. Any offending items are then eliminated. After the sorters have been set with the required parameters, they inspect size tolerance, check for surface defects, such as flash and air-bubbles, and ensure the O-rings are perfectly flat, which is essential if they are to be machine-assembled properly. The next step takes place in a test laboratory, which is equipped with high-precision instruments, including hardness testers, thickness gauges, automatic projectors, callipers, thermostatic baths, and ovens. These instruments are set and calibrated periodically by third-party organisations accredited by SIT, Italy’s national calibration service. Each delivery comes with its own Final Testing Report, a checklist of the quality controls conducted during the production process.