At LAV.EL. Gomma, quality is the cornerstone of every sector, including material analysis.

LAVEL Lab is our on-site research and development laboratory, and it was opened to offer customers an additional guarantee that we will find the most suitable materials for their requirements.

The laboratory managers use the latest equipment to conduct indepth analysis on a range of materials in a bid to offer clients all of the technical support they need to find the best operating solutions. Furthermore, all of our inhouse quality and reliability tests comply with the latest quality, safety and environmental regulations.

As this new laboratory is on-site, it provides invaluable production-process support and enhances stability and flexibility, as it is equipped for all development and production requirements.

Our laboratories conduct the following tests:

Characterisation of materials

- Fourier-Transform Infrared Spectroscopy (FT-IR): identifies a product’s chemical nature.

- Differential Scanning Calorimetry (DSC): establishes a material’s glass transition (GT) and tests vulcanisation.

- Thermogravimetric Analysis (TGA): measures blend composition quantitatively

Physical and Mechanical Tests

- Hardness tests for elastomers (Shore A)

- Hardness tests for products (IRHD)

- Compression set

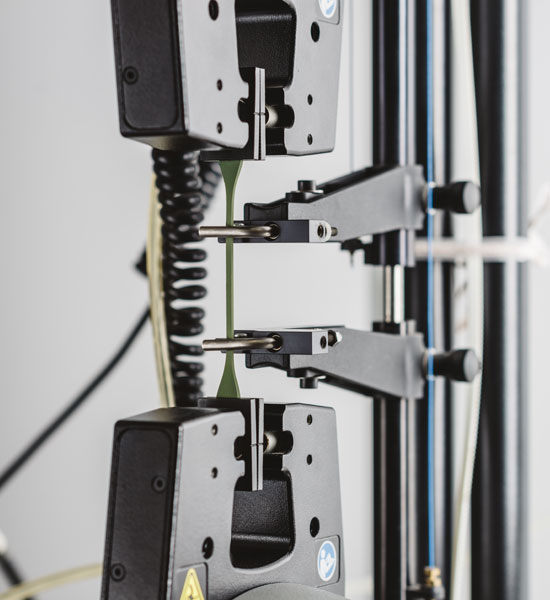

- Dynamometer testing (tensile strength, elongation at break)

- Coefficient of friction measurement tests

Ageing tests

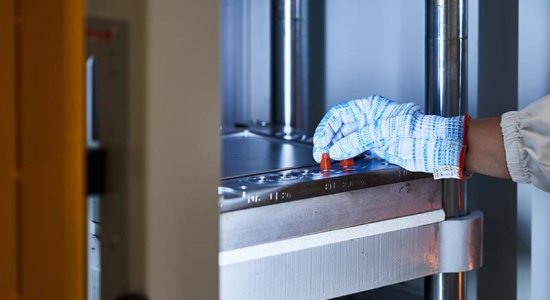

- Oil baths, aluminium heater and sample-immersion equipment

- Tests in water, oils, fluids and other solutions